Oxidized Bitumen 115/15

Description of Oxidized Bitumen 115/15 PARS BITUMEN

Our Factory (Pars Bitumen) is very well-known for the production of Oxidized Bitumen, especially the very highly consumed grade which is Oxidized Bitumen 115/15. This oxidized grade of Bitumen is also manufactured on pure petroleum bitumen basis exactly like other grades at the same category of Oxidized Bitumen. Oxidized Bitumen is commonly processed by blowing enormously hot air into Vacuum Bottom in an extremely hot temperature via some meddling pipes. This grade of Oxidized Bitumen is highly recommended to the customers for various applications which you can see at below section of Applications of Oxidized Bitumen. PARS BITUMEN 115/15 Oxidized Bitumen is a semi-solid Oxidized Bitumen which undergoes the category of polycyclic aromatic hydrocarbons bitumen. Oxidized Bitumen is normally used for different purposes in the construction business globally. PARS BITUMEN Oxidized Bitumen 115/115 burdens a very remarkable softening point, rewarding flash point and it has highest characteristic in its stability enduring melting.

PARS BITUMEN 115/15 Oxidized Bitumen is a bituminous product manufactured by very special process of NON-OXIDATION but MODIFICATION of VACUUM BOTTOMS at 230 C temperature, which results in producing absolutely penetration content material. This product is dramatically applied in the industrial sections and presents predominantly “solid” characteristics at ambient temperatures and provides superior adhesive and waterproofing qualities when used in hot format and shall be allowed to cool rather than other types of Oxidized Bitumen.

PARS BITUMEN company is extremely responsible on outstanding quality issues of its Oxidized Bitumen 115/15 and is available to arrange any inspection type to check the quality such as pre-delivery inspection, production inspection and loading inspection supervised by the international renowned inspectors to check the cargo in qualitative and quantitative aspects. PARS BITUMEN 115/15 Oxidized Bitumen extremely in in compliance with ASTM standards.

Applications of Oxidized Bitumen 115/15

Oxidized Bitumen 115/15 is very welcome in countries which are developing their construction infrastructures. This grade main use is at Construction and building insulation. Also it is extensively applied as raw material in factories for manufacturing of vast number of products such as bitumen coating, producing chemical fuel, paint production, lacquers, varnishes, paper-pulp-board, textile processing, road construction, ,crack seal and repairing, civil works, construction industries, pavement, sealing , preparation of building insulation, insulation and isolation bitumen membrane sheets, as additive to adhesives production, used as additive to construction materials, dust-binding, producing impregnating agent, production of rubber and finally manufacturing plastic materials. Furthermore, Oxidized Bitumen 115/15 is applied to produce “mopping-grade” roofing asphalts. It is necessary to point out that the special use of Oxidized Bitumen 115/15 is bitumen paint production a

oxidized Bitumen

nd oil well drill fluid. Oxidized Bitumen 115/15 is also highly used by some customers to aid roofing production plants, .shingles production, rolling goods, and built-up roofing felts

Application Method of Oxidized Bitumen 115/15

PARS BITUMEN Oxidized Bitumen 115/15 must be heated with double temperature against the softening point to be make flow and viscosity. The norm for heating degree of Oxidized Bitumen 115/15 is up to 230 ᵒc and if it is inside of bitumen bag, extra temperature approx. 50 ᵒc more is needed.

Before using this type of Bitumen make sure that the surfaces must be dry, clean and free of any dust or loose particles, or any curing products, irregularities, and slurry. Pay attention that if you use this type of asphalt without cleaning the area, the bitumen 115/15 will be easily removed from the applied surface.

Storage/handling situation of Oxidized Bitumen 115/15

The life time of PARS BITUMEN Oxidized Bitumen 115/15 is 10 years during which it can undergo multi-time heating and cooling situation. For further information, please refer to MSDS. Longer life time is expected in case of maintaining good conditions of warehousing, to keep the bitumen 115/15 under shelter and out of the rain and sun shine.

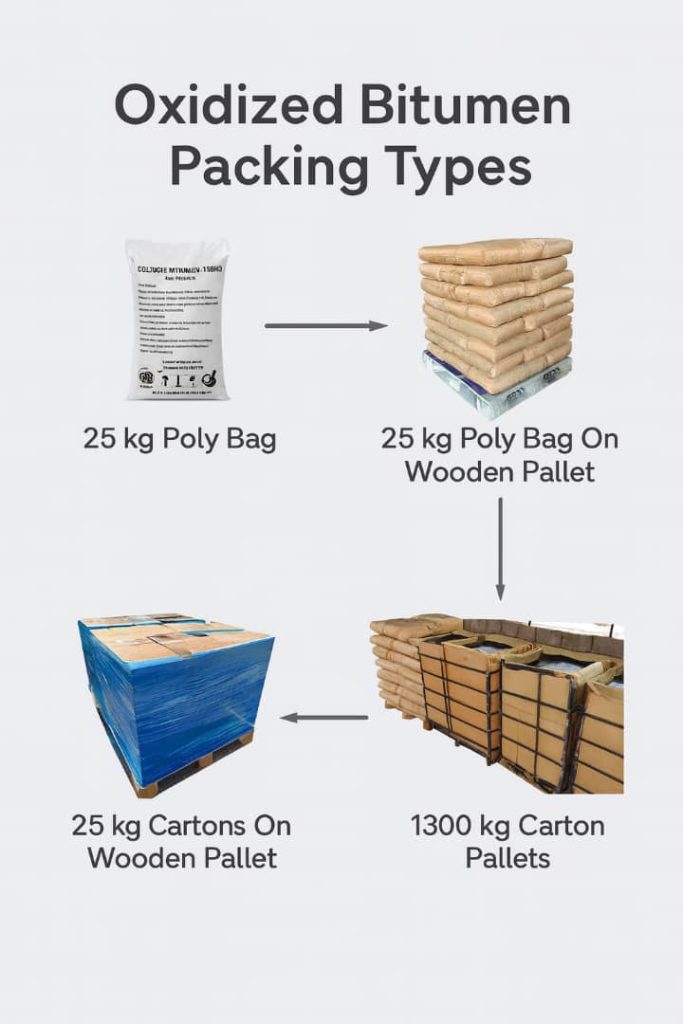

Packing of Oxidized Bitumen 115/15

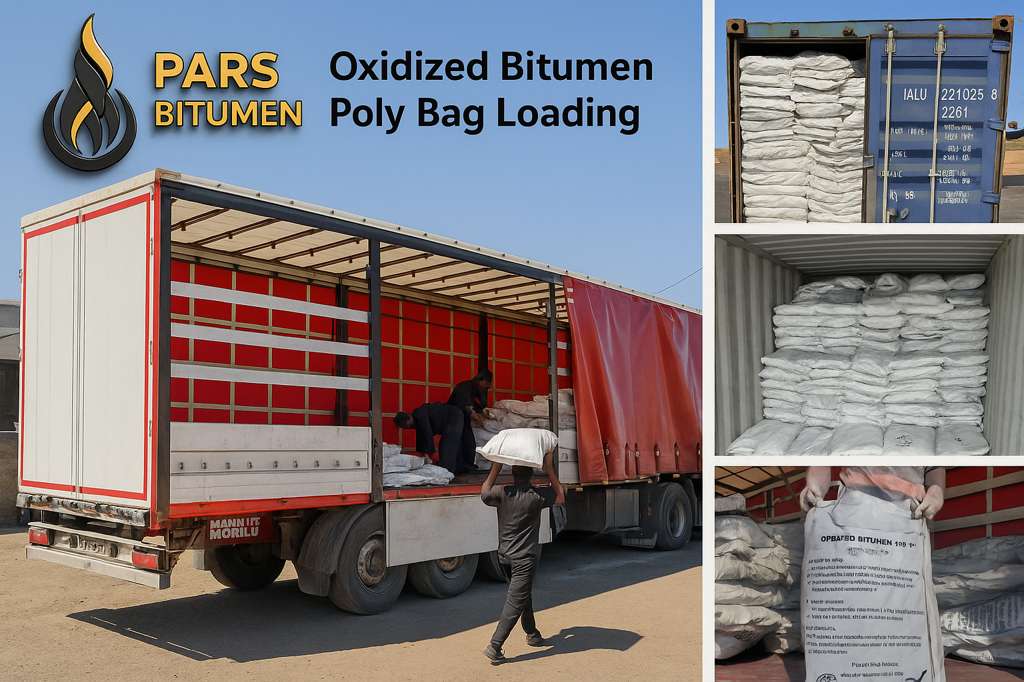

The bitumen 115/15 is packed in different formats such as in bulk, drum, and also meltable 25 kg polyamid bags, polyamide bags or carton boxes. PARS BITUMEN 115/15 is generally shipped as a solid product and then it is then heated in the worksite whenever needed.

You can see some pictures of different packings as below:

oxidized Bitumen Packing Types

oxidized bitumen polybag loading

oxidized bitumen polyamide bags

oxidized bitumen packing

PARS BITUMEN Specification of Oxidized Bitumen 115/15

Analysis Oxidized Bitumen 115/15

| Bitumen 115/15 | Test method | Unit | Specification |

| Specific gravity @25/25 C | ASTM D70 | (Kg/m3) | 1.05 approx. |

| Penetration @ 25°c | ASTM D5 | mm/10 | 10/20 |

| Softening point °c | ASTM D36 | °C | 110/120 |

| Ductility @25 °c | ASTM D113 | Cm | 1.5min |

| Loss on heating(wt) % | ASTM D6 | Wt. % | 0.2 max |

| Flashpoint c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | Wt. % | 99.5 max |

| Spot test | A.A.S.H.O.T102 | — | Negative |

Contact Pars Bitumen:

🌐 Website: www.parsbitumen.com

📧 Email: sales@parsbitumen.com

📞 WhatsApp: +98 912 387 9127

Written and Gathered by Pars Bitumen

Pars Bitumen Logo