Cutback versus Emulsion Bitumen

Cutback Bitumen vs. Emulsion Bitumen: A Complete Comparison by Pars Bitumen

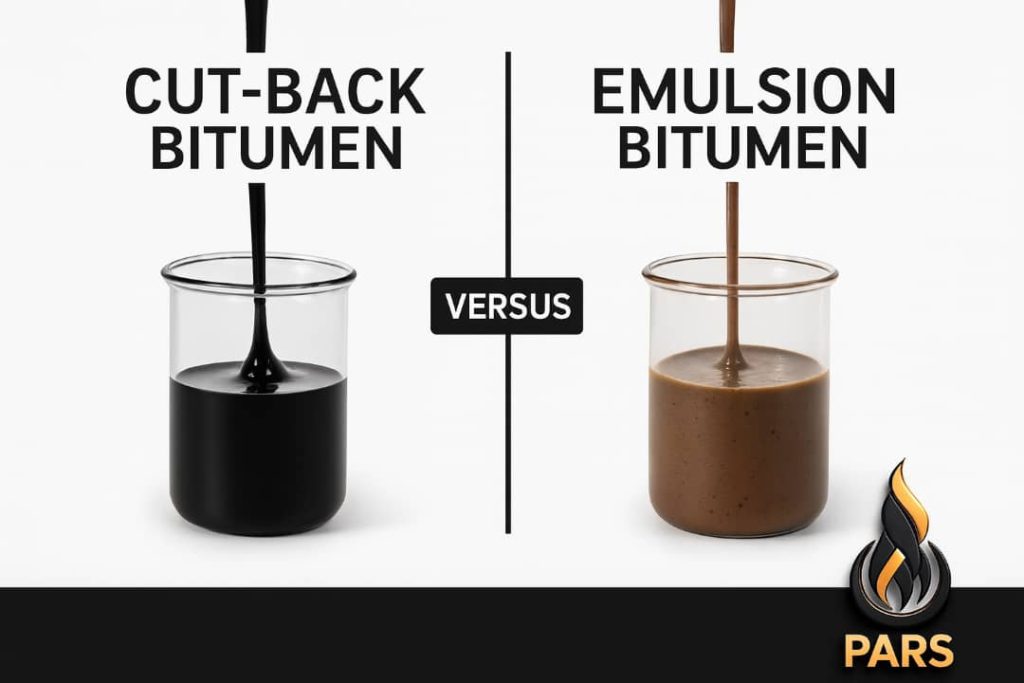

cutback bitumen versus emulsion bitumen

Introduction

Bitumen is a key binding material widely used in road construction, waterproofing, and industrial applications. Among the various types, Cutback Bitumen and Bitumen Emulsion are two of the most commonly used forms. Although both serve similar purposes, their composition, performance, and environmental impact differ significantly. In this article, Pars Bitumen, a leading manufacturer and exporter of high-quality bitumen in Iran, explains the major differences between Cutback Bitumen and Emulsion Bitumen, helping you choose the right type for your specific project.

What is Cutback Bitumen?

Cutback Bitumen is produced by blending penetration-grade bitumen with a solvent such as kerosene, naphtha, or diesel. The solvent temporarily reduces the viscosity of the bitumen, making it easier to apply without heating. Once applied, the solvent evaporates, leaving behind a layer of pure bitumen that binds the aggregates.

Main Types of Cutback Bitumen:

Rapid Curing (RC) – Uses highly volatile solvents (e.g., RC-70, RC-250, RC-800).

Medium Curing (MC) – Contains moderately volatile solvents.

Slow Curing (SC) – Uses heavy oils or diesel with slow evaporation.

Advantages:

Ideal for cold weather applications.

Excellent adhesion with aggregates.

Quick setting and suitable for spray sealing and patch repairs.

Disadvantages:

High VOC emissions due to solvent evaporation.

Flammable and hazardous during handling.

Less eco-friendly compared to emulsion bitumen.

What is Bitumen Emulsion?

Bitumen Emulsion is a mixture of bitumen, water, and an emulsifying agent. The bitumen is dispersed in water in the form of tiny droplets stabilized by the emulsifier. This allows the bitumen to be applied at ambient temperature without heating or using harmful solvents.

Types of Bitumen Emulsion:

Cationic Emulsion (Positive charge) – Bonds well with negatively charged aggregates.

Anionic Emulsion (Negative charge) – Suitable for positively charged aggregates.

Advantages:

Environmentally friendly and safe to use.

Energy-efficient, as no heating is required.

Ideal for damp conditions where cutback cannot be used.

Reduces fire and fume hazards on site.

Disadvantages:

Slower curing time compared to cutback.

Requires proper storage and temperature control.

Less effective in very cold climates.

Applications: Cutback vs. Emulsion Bitumen

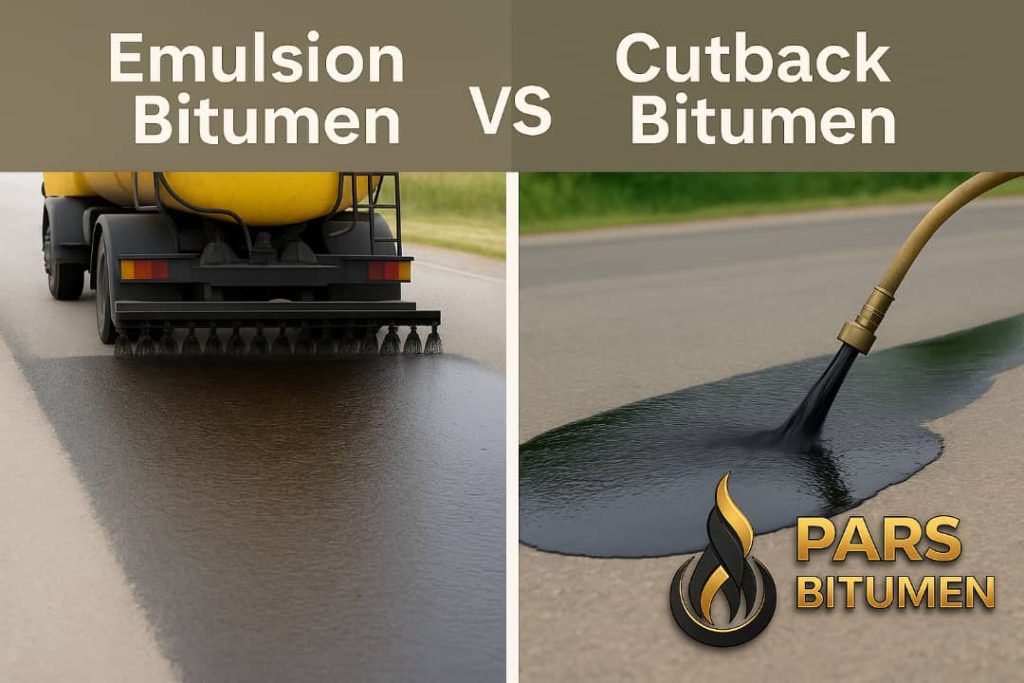

Application of cutback bitumen versus emulsion bitumen

Application Cutback Bitumen Emulsion Bitumen

Surface Dressing Excellent for cold climates Ideal for moderate climates

Patching & Repairs Quick repair works Suitable for wet conditions

Prime Coat Commonly used on granular surfaces Water-based, safer for environment

Tack Coat Provides strong bond between layers Preferred for eco-friendly projects

Cold Mix Asphalt Used with slow-curing grades Cationic emulsions widely used

Dust Binding Frequently used Limited use.

Environmental and Safety Considerations

With increasing focus on sustainability, Bitumen Emulsion is gaining preference worldwide due to its eco-friendly nature. It eliminates the use of volatile organic solvents, making it safer for workers and the environment. In contrast, Cutback Bitumen, though effective, releases hydrocarbon vapors that contribute to air pollution and pose safety risks during transportation and application.

At Pars Bitumen, we ensure that both our Cutback Bitumen and Emulsion Bitumen products meet international standards for quality, performance, and environmental safety. Our production facilities in Iran are equipped with modern technology to deliver high-performance materials suitable for all road construction and industrial applications.

Conclusion

Choosing between Cutback Bitumen and Emulsion Bitumen depends on your project’s climate conditions, application method, and environmental priorities.

If you need quick-setting material for cold or emergency repairs, Cutback Bitumen is the right choice.

For eco-friendly and safer operations, Bitumen Emulsion is more suitable.

Pars Bitumen offers a complete range of both types, tailored to meet your construction needs. Whether you’re building new roads or maintaining existing infrastructure, our expert team ensures top-quality bitumen solutions for durable and sustainable results.

Keywords:

Cutback Bitumen, Bitumen Emulsion, Cutback vs Emulsion Bitumen, Bitumen Types, Road Construction Bitumen, Pars Bitumen, Bitumen Manufacturer Iran, Emulsion Bitumen Supplier, Cutback Bitumen Supplier.

Contact Pars Bitumen

🌐 Website: www.parsbitumen.com

📧 Email: sales@parsbitumen.com

📞 WhatsApp: +98 912 387 9127